HDPE vs. PVC MESH NETS: WHAT ARE THE DIFFERENCES?

Discover the World of mesh nets: From Applications to Materials

Mesh netc, critical in various applications such as agriculture, gardening and construction projects, comes in a variety of materials.

Two commonly used options are HDPE (High-Density Polyethylene) and PVC (Polyvinyl Chloride).

In this blog, we’ll take an in-depth look at the differences between HDPE and PVC mesh netting and help you make the right choice based on your specific needs.

HDPE MESH NETS: STRENGTH AND DURABILITY

HDPE mesh netting are manufactured from high-density polyethylene, a plastic known for its impressive strength and durability.

These properties make HDPE mesh netting ideal for situations where resistance to tensile forces and abrasion is essential.

Here are some of the key benefits of HDPE mesh netting:

Weather Resistance: HDPE mesh netting can be used in a variety of weather conditions. Ranging from sunny to rainy, without significant wear and tear.

Longevity: Thanks to their durability, HDPE mesh nets last a long time and require minimal maintenance.

Environmental Friendliness: HDPE is recyclable, making it a sustainable choice for mesh netting.

Versatility: HDPE mesh netting is suitable for use in gardens, as livestock fencing and even in the construction industry.

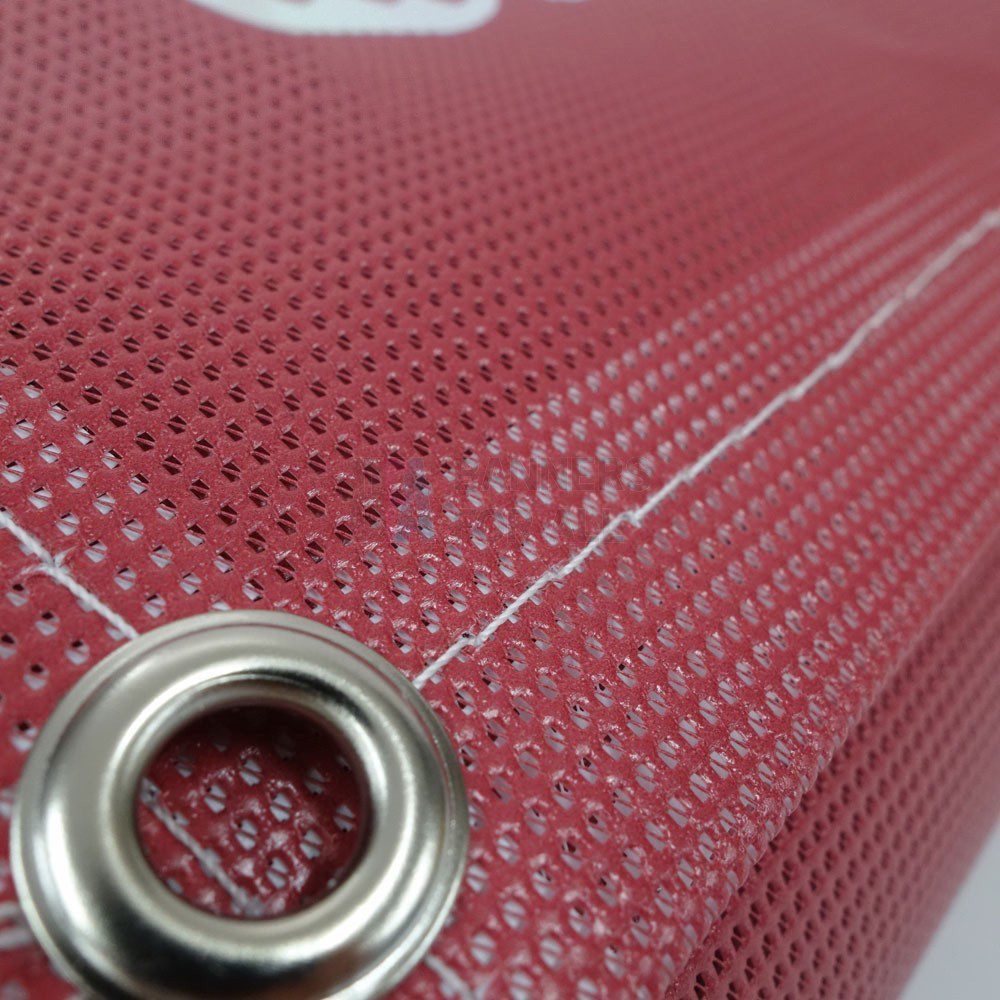

PVC MESH NETTING: FLEXIBILITY AND CHEMICAL RESISTANCE

PVC mesh netting, manufactured from polyvinyl chloride, are distinguished by their flexibility and resistance to chemicals.

They are particularly suitable for applications where HDPE may not be the most suitable option. Some key features of PVC mesh are:

Chemical Resistance: PVC mesh netting is resistant to chemicals, acids and oils, making it ideal for industrial applications.

Flexibility: PVC mesh netting can be used in various configurations because of its ductility.

Visibility: Thanks to their transparency, PVC mesh nets are excellent for situations where visibility is important, such as in the construction industry.

Weight: In general, PVC mesh nets are lighter than HDPE mesh nets, making them suitable for mobile applications.

CHOOSING THE RIGHT MESH NET FOR YOUR NEEDS

When choosing between HDPE and PVC mesh netting, it is crucial to consider which properties are most important for your specific application.

If you are looking for a robust and durable material that can withstand the elements, HDPE mesh netting is the right choice.

On the other hand, if you need flexibility, chemical resistance and visibility, PVC mesh netting may be a better option.

It is also important to remember that both HDPE and PVC mesh netting are available in various sizes and configurations, allowing you to customize the mesh netting to meet your specific needs.

CONCLUSION

In summary, HDPE and PVC mesh netting each offer unique features and benefits.

By taking into account the nature of your project and the requirements of your application, you can make the right choice and ensure that the mesh netting meets your expectations.

Mesh nets are invaluable in countless projects, and an informed choice can provide significant benefits in terms of performance and durability.

Whether you choose HDPE or PVC mesh netting, both materials are extremely useful within their own context and offer reliable solutions for a variety of situations.

In short, HDPE and PVC mesh netting are both valuable choices depending on your specific needs.

Also read: Nets